What is ALD, CVD, MLD?

- The world of nanotechnology and impact on everyday life might seem a few years or even decades away, but in fact nanotechnology already exists in our everyday life. Thin film coatings manufactured using ALD, CVD, and MLD technologies are enabling technologies for nanotechnology.

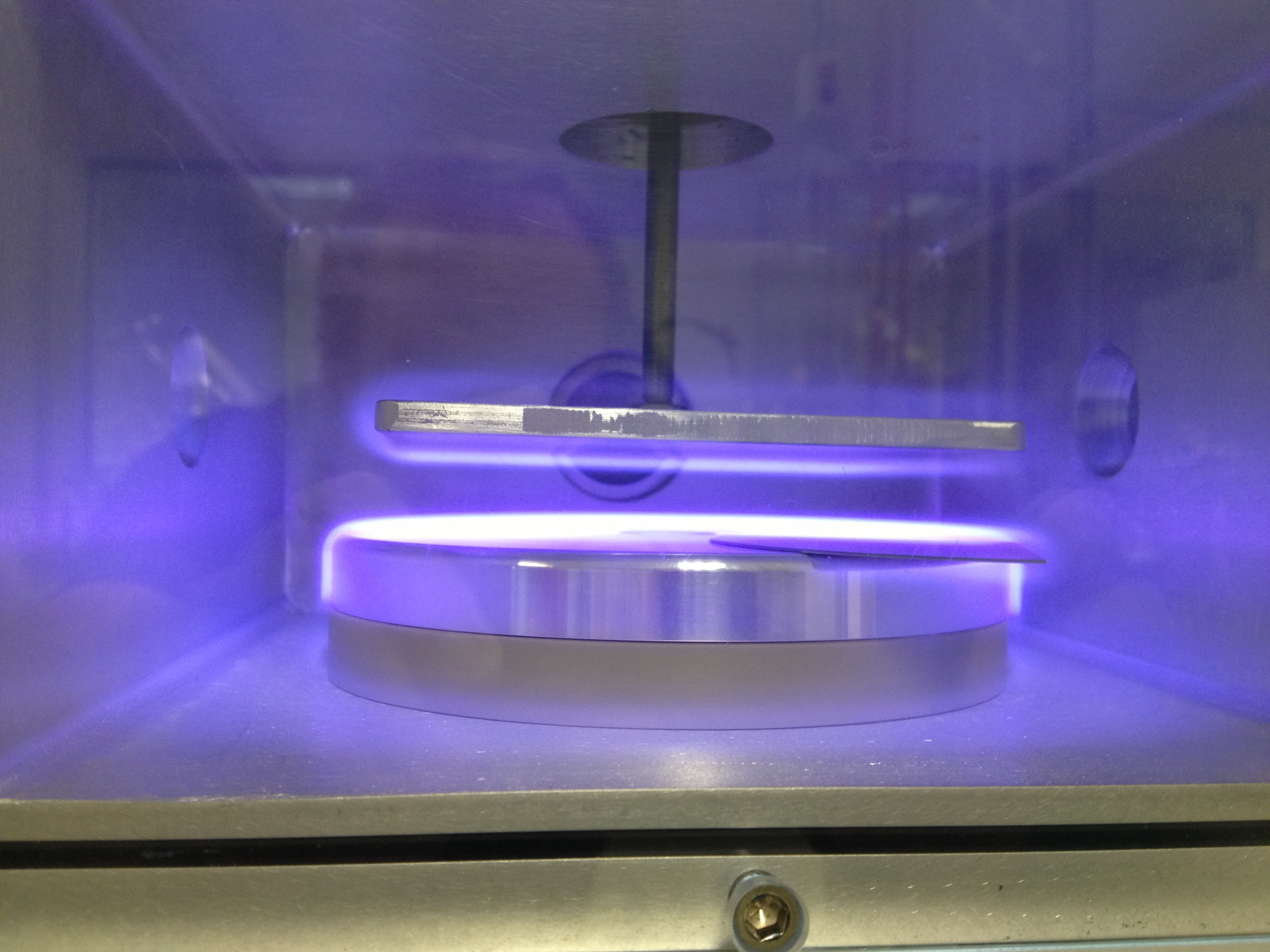

- What is Atomic Layer Deposition (ALD)? ALD is a thin-film deposition technique that offers precise control over the thickness and composition of coatings at the atomic level. ALD works through a series of self-limiting chemical reactions to deposit layers of material atom-by-atom, which allows for extremely uniform and conformal films. This method is especially useful for applications requiring exact thickness and material properties, such as in semiconductors, solar panels, and various nano-fabrications. The precision and versatility of ALD make it a crucial tool in advancing microelectronics and other technologies that require nanoscale engineering.

- What is Chemical Vapor Deposition (CVD)? CVD is a widely used technique in materials engineering for creating high-quality, high-performance solid materials. This process involves the deposition of a solid material from a gaseous phase onto a substrate through a chemical reaction. CVD is particularly valued for its ability to produce uniform coatings on complex geometries and is extensively used in the fabrication of semiconductors, thin films, and various nanostructured materials. The ability to control the properties of the deposited material—such as composition, thickness, and crystallinity—makes CVD indispensable in numerous high-tech manufacturing processes.

- What is Molecular Layer Deposition (MLD)? MLD is a vapor-phase deposition technique that allows for the fabrication of ultra-thin films with molecular-level precision. Similar to ALD, MLD relies on sequential, self-limiting surface reactions to achieve conformal coatings, but it uses organic and hybrid organic-inorganic precursors to build the film, layer by layer. This capability to deposit organic materials makes MLD uniquely suited for applications in organic electronics, barrier coatings, and the integration of organic components into nanostructured devices. MLD’s precision and versatility enable the development of advanced materials with tailored functionality and improved performance.

- VaporPulse has direct experience using ALD, CVD, and MLD to functionalize and protect materials used in many industries including Defense, Energy, Medical, Packaging, Optics and Electronics for applications such as UV protection, smart textiles, flexible electronics, corrosion, moisture barriers, and flame retardants.

Interested in talking about how VaporPulse can be helpful, contact us to start a discussion.